Install the circulator on the delivery pipe or on the return pipe. The arrow stamped on the pump body indicates the direction of flow.

Install an on-off valve on both the suction pipe and the delivery pipe.

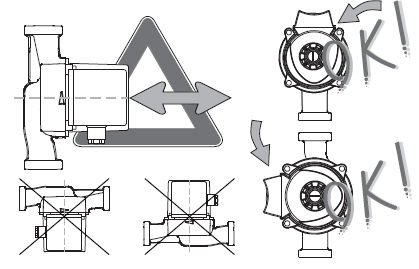

ALWAYS fit the circulator with the motor shaft horizontal, avoiding dripping onto the motor and onto the terminal board.

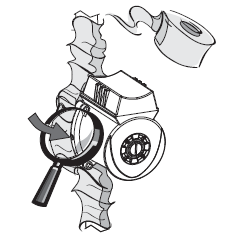

In case of thermal insulation, ensure that the condensate drainage holes in the motor casing are not closed or partially blocked.

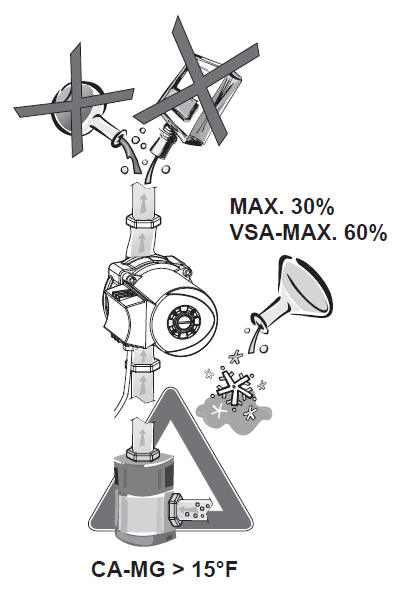

Do not mix additives derived from hydrocarbons and aromatic products with the circulating water. Antifreeze max. 30% (VSA max. 60%). Provide an anti-scale system in plants having domestic circulators with water total hardness (TH) higher than 15°F.

In the electrical connection to the power supply line, provide a two-pole switch with a contact opening distance of at least 3 mm. No motor overload protection is required. The instruction manual of the VS circulator (also available in our DNA software) provides all the indications to follow for the use of the product.