This procedure applies to new installations as well as after service inspections if start-up takes place sometime after the pump was placed in the tank.

- After long periods of storage, check the conditions of the oil in the oil chamber.

- Check that the system, bolts, gaskets, pipework and valves etc. are in correct condition.

- Mount the pump in the system.

- Switch on the power supply.

- Check whether the monitoring units, if used, are operating satisfactorily.

- Check the setting of the float switches or of the level sensors.

- Check that the impeller can turn freely by briefly starting the motor.

- Check the direction of rotation.

- Open the isolating valves, if fitted.

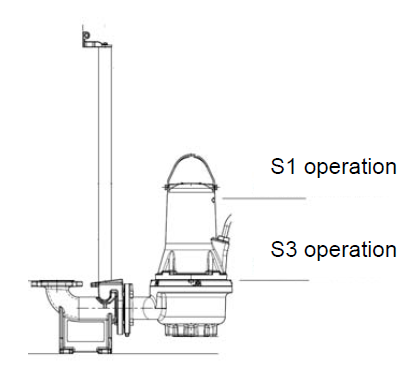

- Check that the liquid level is above the motor for S1 operation and above the cable entry for S3

operation. If the minimum level is not reached do not start the pump.

- Start the pump and let the pump run briefly, and check if the liquid level is falling.

- Observe if the discharge pressure and input current are normal. If not, there might be air trapped inside the pump

The product manual available here on our site or here in our DNA software provides more information for this product usage and maintenance.